The Capabilities of Multilayer PCBs: From Individual Prototypes to Mass Production

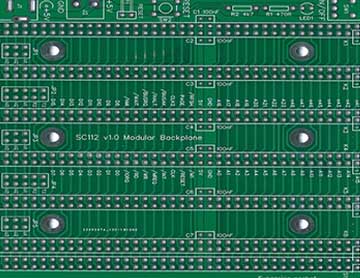

Multilayer printed circuit boards (PCBs) have become increasingly popular in the technology industry, due to their ability to accommodate more complex designs and increase the density of components on a single board. With the capacity to manufacture up to 36 layers, multilayer PCBs provide a versatile solution for a wide range of applications, from individual prototypes to small batches and mass production. In this blog, we will explore the capabilities of multilayer PCBs and the advantages of using them for your next project.

Advantages of Multilayer PCBs:

1. Increased Density

Multilayer PCBs allow for increased density of components on a single board, resulting in a more compact and efficient design.

2. Improved Electrical Performance

By having multiple layers, multilayer PCBs can provide improved electrical performance, as each layer can be used for a specific purpose, such as power distribution or signal routing.

3. Reduced Component Count

With the ability to integrate multiple functions onto a single board, multilayer PCBs can reduce the component count, resulting in a more cost-effective solution.

4. Increased Reliability

By having multiple layers, multilayer PCBs can provide increased reliability and reduce the risk of electrical failures.

5. Small Batch and Mass Production

Multilayer PCBs can be manufactured in both small batches and mass production quantities, making them a versatile solution for a wide range of projects.

Conclusion

In conclusion, multilayer PCBs provide a versatile solution for a wide range of applications, from individual prototypes to small batches and mass production. With the capacity to manufacture up to 36 layers, multilayer PCBs provide increased density, improved electrical performance, reduced component count, increased reliability, and the ability to accommodate both small and large quantities. When choosing a supplier for your multilayer PCB needs, be sure to choose a company with experience and a proven track record for delivering high-quality, reliable solutions.